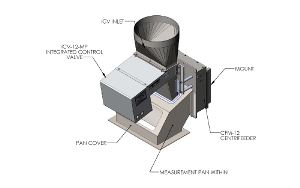

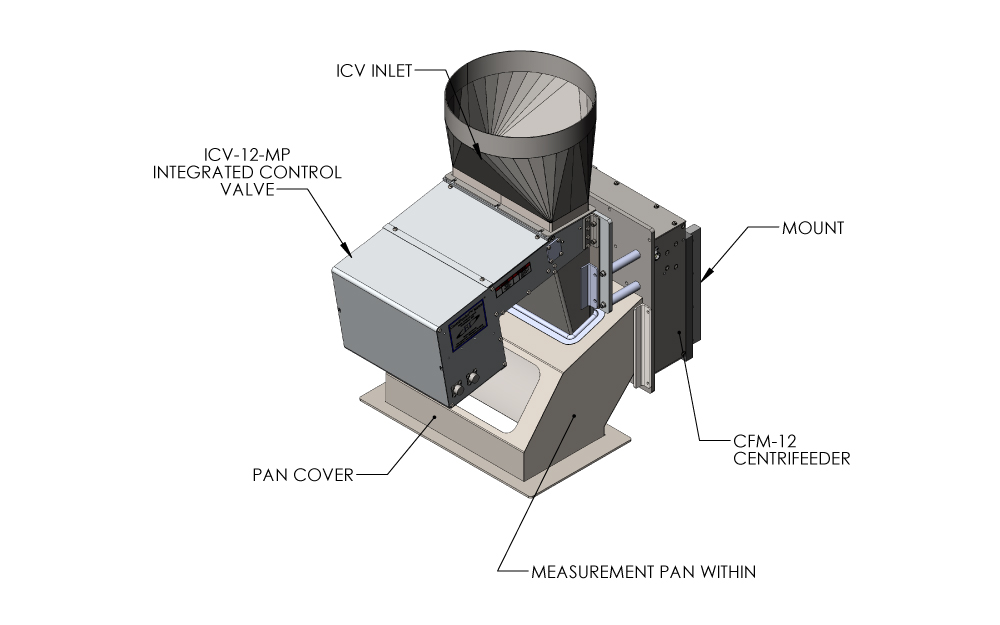

CENTRIFEEDER ICV: BULK DENSITY MEASUREMENT

The CentriFeeder line of feeders allows for both an accurate, real-time flow measurement, as well as near perfect control of flow rate and total. For blending applications, control the flow rate of an individual ingredient, or combine several CentriFeeders for near perfect recipe control. If you are controlling ingredients entering a batching process, use the CentriFeeder for controlling the total of one or more ingredients entered into the batch.

Please see below for additional information regarding the use of the CentriFeeder ICV as a bulk density flow measurement device. The Bulk Density of the product flowing through the CentriFeeder ICV will be output every second as a live, dynamic reading of the bulk density of the flowing product.

CENTRIFEEDER ICV: BULK DENSITY MEASUREMENT

CENTRIFEEDER ICV: FILLING

The Dynamic Bulk Density Measurement System is a gravimetric measurement system used to dynamically measure the bulk density of granular flowable solids while in process. Offering a true bulk density output as well as outputs for both mass flow rate and totalization, the BDM gives you the ability to manage your process by monitoring or controlling the product stream's bulk density or by maintaining a throughput of a specified density of product in order to control blends of different densities of materials. The Dynamic Bulk Density Meter is a true bulk density meter that actually measures, rather than calculates, the bulk density of a flow of material. But how do we attain

the high level of accuracy that your process demands? The answer lies in the technology that informs all of Eastern Instruments' solids flow measurement and control products.

DYNAMIC BULK DENSITY METER:

![]()

GRANULAR MATERIALS

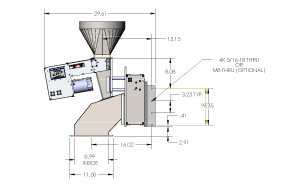

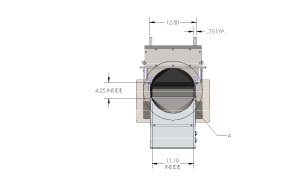

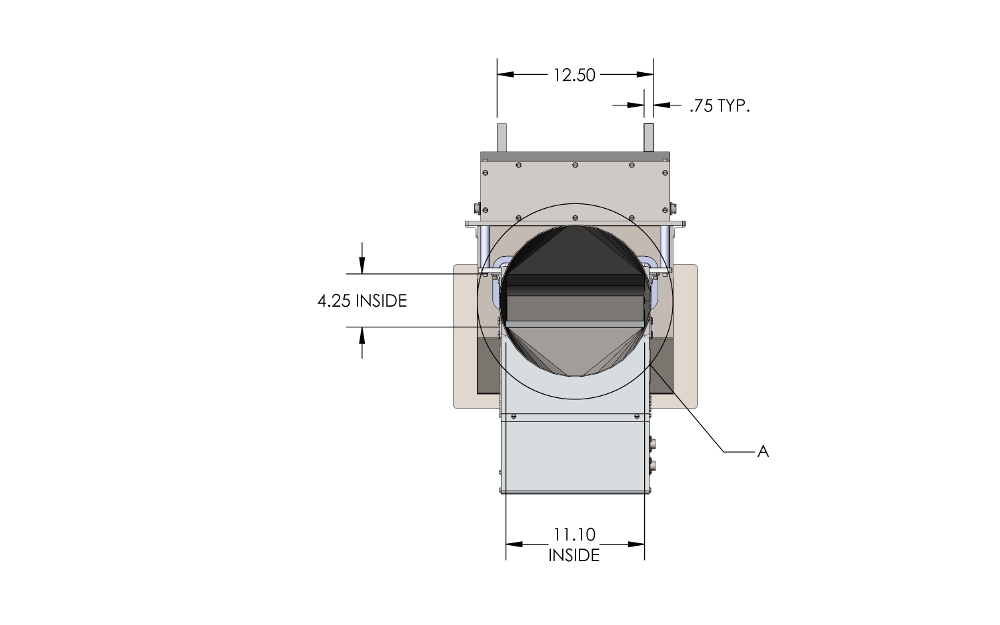

Because the Dynamic Bulk Density Meter utilizes the pinpoint accuracy of an integral slide gate, it requires a head of product in order to run optimally. As such, the meter can be mounted in one of two locations. Statically mounted, the Dynamic Bulk Density Meter is typically mounted directly under an existing head of product such as a silo or bin. When Dynamically mounted, the meter is typically mounted directly in process and requires the use of an optional flow tracking hopper. In either mount orientation, product flows from the head of product(bin/silo or Flow Tracking Hopper), through the integral slide gate and across the mass flow measurement pan. The measurement, at its most basic, is a function of the equation:

DENSITY= MASS/VOLUME

Accurate and dependable bulk density measurement is rooted in an accurate mass flow measurement. Utilizing patented CentriFlow mass flow measurement technology which is based on the principal of Centripetal Force, a true mass flow measurement is obtained as the entire product stream passes over the Measurement Pan (no sampling). Meanwhile, the Integrated Control Valve, which is controlled to within 1 part in 1000 (based on stroke) ensures an extremely precise real time measurement of the volume of product while its mass flow is being measured. The result is a highly accurate, dynamic, bulk density measurement.

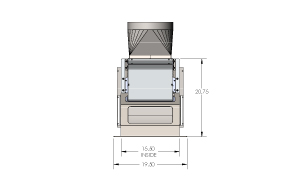

VOLUMETRIC CAPACITY OF THE CENTRIFEEDER

BULK DENSITY METER FOR GRANULAR PRODUCTS |

| Meter Size |

| CAPACITY | CF-06 | CF-12 | CF-24 |

| MIN | 2.03 ft3/min

3.44 m3/hr | 4.50 ft3/min

7.65 m3/hr | 9.00 ft3/min

15.29 m3/hr |

| MAX | 12.15 ft3/min

20.64 m3/hr | 27.00 ft3/min

45.87 m3/hr | 54.00 ft3/min

91.75 m3/hr |

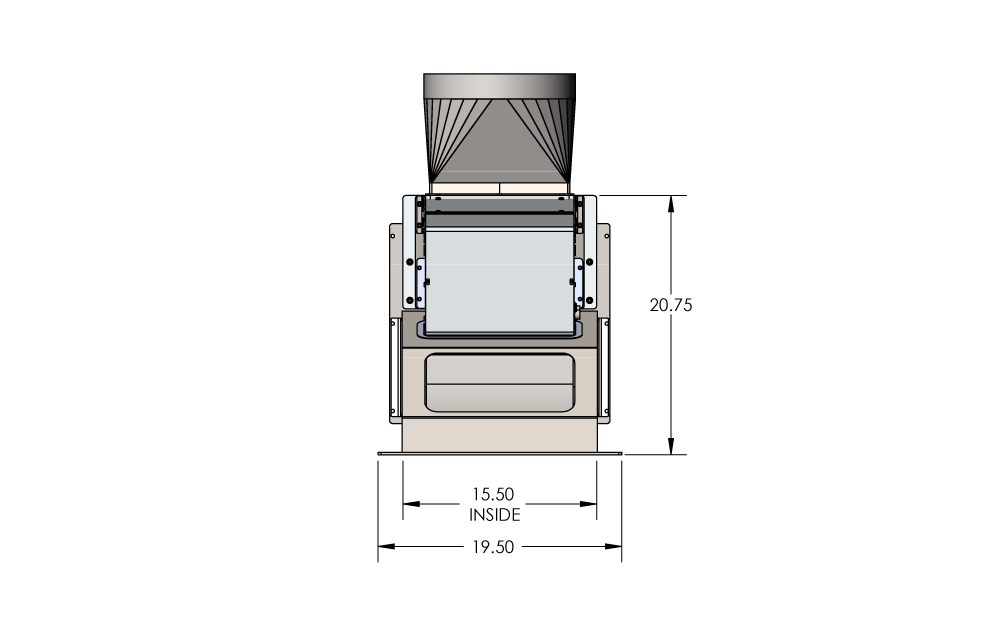

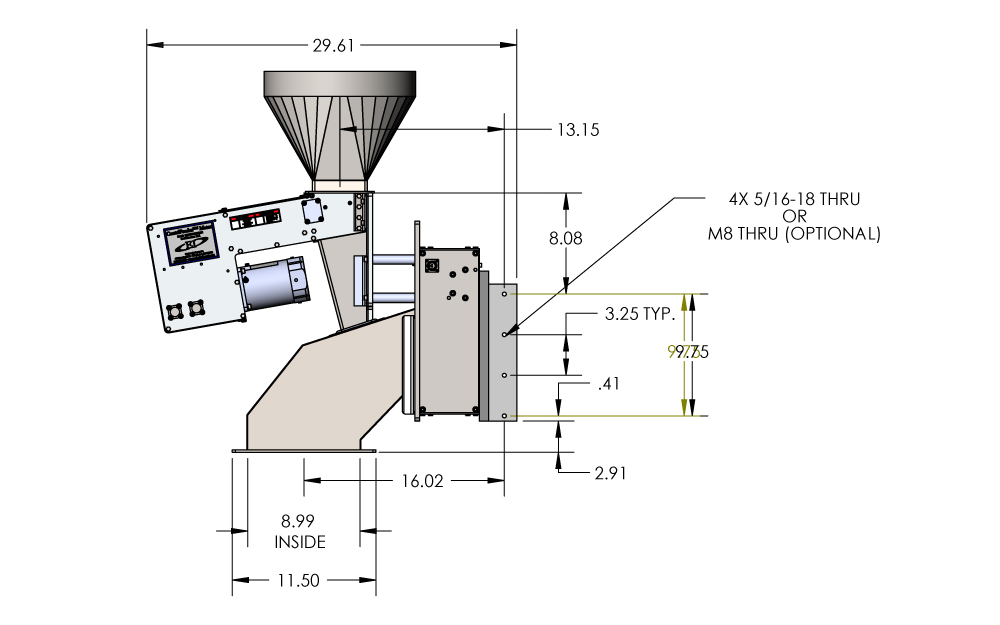

STANDARD CENTRIFEEDER ICV

×

1 / 4

2 / 4

3 / 4

4 / 4

❮

❯