CENTRIFEEDER MCV: ELECTRONICS

The CentriFeeder line of feeders allow for both an accurate, real-time flow measurement, as well as near perfect control of flow rate and total. For blending applications, control the flow rate of an individual ingredient, or combine several CentriFeeders for near perfect recipe control. If you are controlling ingredients entering a batching process, use the CentriFeeder for controlling the total of one or more ingredients entered into the batch.

The CentriFeeder MCV Integrates a flow measurement device with the flow control capabilities of an integrated slide gate to accurately measure and control the flow of any dry, free-flowing solid that can be controlled using a slide gate. Through the use of a highly customizable touch screen HMI, a PID control loop is established that modulates the slide gate feeding our patented flow measurement device. The outcome is an accurate, easily maintained, consistent flow that can be used for mixing, ratio control, or even bulk density measurement.

CENTRIFEEDER MCV REMOTE ELECTRONICS

The CentriFeeder Digital Electronics is a remote electronics package that comes standard with every CentriFeeder. The electronics allows the user to enter a set-point based on either flow rate or totalization and to control the flow of product to that set-point. The standard electronics cable that comes with each meter, measures 10 feet in length, but the length of the cable can be customized for installation in remote locations such as control rooms which can be several hundred feet from the feeder's installation location. Below are just some of the remote electronics package's features and benefits:

- White painted Carbon Steel Enclosure (12" x 14" x 8") SS NEMA 4X also available

- Digital CentriFlow Electronics Module (DCE)

- Flow Rate and Totalization Outputs: (4-20 mA and Frequency Outputs)

- Option for no-calibration setup so that the feeder will be ready out of the box

- Remote Reset Capabilities

- Flow Rate and Totalization Alarm/Preset Capabilities

- Large, convenient, color, touch screen HMI

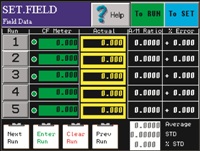

- Main Run Page that displays both Flow Rate and Totalization simultaneously

- Universal Power Supply (85-264 VAC)

- Gigabyte compact flash card that records data every second for up to 1 year

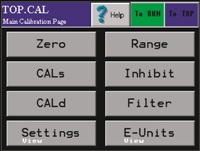

- User friendly, push button calibration

- HMI On-screen plotting/trending and more!

- Remote Communications Protocol Including Ethernet/IP and ProfiBus

- OUTPUTS TO PLC:

- Flow Rate

- Total

- Remote Zero Read-back

- Remote Alarm Target Read-back

- Meter Casing Temperature

- Valve Position

- Set-point Read-back

- Valve State Open/Closed

- INPUTS FROM PLC:

- Remote Reset

- Remote Zero

- Remote Calibration

- Start/Stop Valve

- Clean Valve

- 4-20 mA Filter that allows smoothing of the otherwise instantaneous output delivered by the meter

- Multiple Calibration option for up to 8 distinct calibrations