SIMPLE INSTALLATIONTypical installations require only 3 feet of vertical height and can be set up and running within a single day. TWO MODES OF OPERATION

Manual Mode allows for customized control of individual fill cycles, while Automatic Mode allows for automatic sequencing of complex, multi-compartment fills.

RUGGED CONSTRUCTIONThe CentriFlow Meter is made of Anodized Aluminum and Stainless Steel components (All Stainless Steel models are available) and can be mounted outdoors directly in the elements. Various flow surfaces are available for the meter, including ceramic tile lined flow surfaces for especially abrasive materials.

VERSATILITYCan be used to fill both railcars and trucks with nearly any product that is being transported via gravity, including pellets, powders, grains and more.

ADAPTABILITY

The unique fill algorithm that determines when to shut off the feed of product into the railcar/truck works independently of flow rate and will ract dynamically to changes in flow rate, even when flow rate changes during the fill.

EXTREME ACCURACY

The fill accuracy of the Railcar and Truck Loadout System can be as accurate as +/-0.25%.

UNIVERSAL DESIGN

The Railcar and Truck Loadout System is universal in design and can be used for nearly any setup where trucks or railcars are being filled.

EASY TO USE

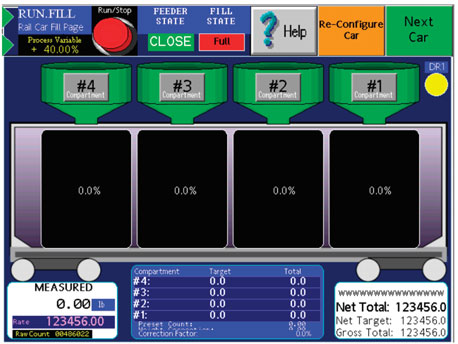

The Loadout System comes with a color touchscreen HMI interface so that setup and use of the system is as easy as the push of a button.

|