VAP INSERTION STYLE PITOTS FOR COMBUSTION

Pitot tubes are a time-tested method of measuring air flow in combustion ducts. Pitot tubes are easily installed, highly cost-effective, easily maintained and can be inserted into almost any duct configuration including primary, secondary, tertiary and over-fired air ducts to name a few. Although pitot tubes do require upstream and downstream straight duct runs to operate most accurately, they are a very cost effective way to manage boiler trim controls and to maintain control over the fuel-to-air ratio in almost any power generation application.

INTRODUCTION TO TECHNOLOGY

VAP PITOTS IN COMBUSTION AIR

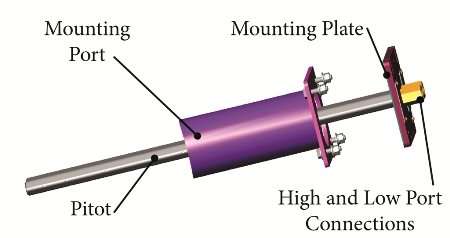

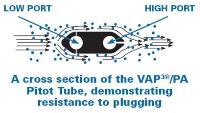

Eastern Instruments' VAP Pitots have a unique Velocity Averaging and Parallel Plate proprietary design. When inserted into the air flow ducts of a power plant (both Round Ducts and Square/Rectangular Ducts), the VAP Pitots provide an accurate, differential pressure output allowing for precise air flow measurement or control of your process. VAP Pitots designed for power plants are designed with Plug resistance in mind as many ducts have particulate in the ducts that normally plug measurement devices and cause dramatic inaccuracies in flow measurement. The VAP PA Pitot (Particulate Applications) can be installed in existing or new ducts or incorporated into flow-conditioning devices, such as the High Beta, designed for short duct run applications with turbulent air flow or to obtain optimal accuracy.

Each VAP Pitot has multiple total and static sensing ports, specifically located to provide a full traverse of the duct, thus eliminating the concern of highly random distribution of air flow. For larger ducts, an array of pitots, with total and static pressure lines manifolded, can be installed to ensure an equal area traversing and fully averaged air flow sampling. The VAP Pitots are erosion resistant and can handle typical process temperatures from -40o to 900oF, with a variety of engineered options available as well.

VAP/PA - PARTICULATE-LADEN APPLICATIONS

A proprietary design for Particulate-laden applications (PA), the VAP/PA air flow measurement pitots are ideal for either new or retrofit processes, and power generation applications. When inserted in air flow ducts, the VAP/PA provides an accurate, differential pressure output allowing for precise air flow measurement and control of your process to as low as +/-2% when calibrated, utilizing a plug-resistant design that resists plugging, even in air streams containing high levels of fly ash or other contaminants. The VAP/PA pitots can also be incorporated within flow-conditioning devices, such as the High Beta, designed for short duct run applications with turbulent air flow, or to obtain the maximum accuracy.