HBP - HIGH BETA PROCESS (INDUSTRIAL)

Air flow measurement is most accurate in straight duct runs where air flow can be evenly profiled across the duct at the point of measurement and where no turbulent, reverse, or cyclonic flow patterns are present. Typically, it can take as much as 10 diameters of straight duct run to eliminate turbulent or reverse flow, while it can take as much as 30 diameters of straight duct run to eliminate cyclonic flow. If you do not have the proper amount of straight duct run present to accurately measure your air flow, some type of flow conditioner is required.

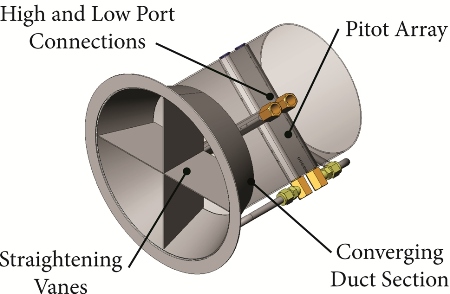

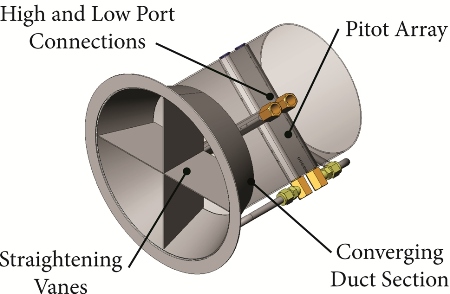

The HBP - High Beta Process Flow Conditioner is ideally designed for industrial process applications where the expansive straight duct runs needed for accurate flow measurement are not present. Perfect for new or for retrofit applications, the HBP is designed for installations with relatively no straight duct runs upstream or downstream and eliminates cyclonic, turbulent and reverse flow at the point of measurement. The HBP consists of a flanged spool section, a converging duct section, a set of straightening vanes and an array of VAP Pitots. The HBP ensures an accurate differential pressure output that provides precise air flow measurement for tighter control of your process.

INTRODUCTION TO TECHNOLOGY

FEATURES AND BENEFITS

|

DUCT SECTION |

24" .707 SS High Beta duct section, available in diameters up to 36".

|

| ACCURACY |

Accuracy to within ±0.5% and repeatability to within ±0.1%. Testing certification in an AMCA rated test chamber is available.

|

| BASIC INSTALLATION |

Includes a flanged duct section for easy installation, while the contained pitot array is internally manifolded and connected via through-wall fittings.

|

| PRIMARY FLOW ELEMENT |

Available with either VAP/SA Pitots for clean air flow applications or with VAP/PA Pitots for particulate-laden applications.

|

| INTEGRAL STRAIGHTENING VANES |

Contains integral flow straightening vanes that eliminate cyclonic, turbulent and reverse flow at the point of measurement.

|

| MATERIAL OF CONSTRUCTION |

304 SS construction. VAP is manufactured of extruded 6063 series aluminum with a final process Teflon hard-anodized coating, ensuring a surface hardness of Rockwell 65C.

|

| MINIMAL PRESSURE LOSS |

Yields a minimal pressure drop of 33% of the differential pressure.

|

| NO MAINTENANCE |

There are no active electronic components or moving parts within the air stream, thus eliminating maintenance costs and ensuring reliability and ease of use.

|

| VELOCITY AVERAGING THROUGHOUT FULL TRAVERSE OF THE DUCT |

VAP Pitot installations provide multiple DP sensing ports, covering the full traverse of any duct.

|